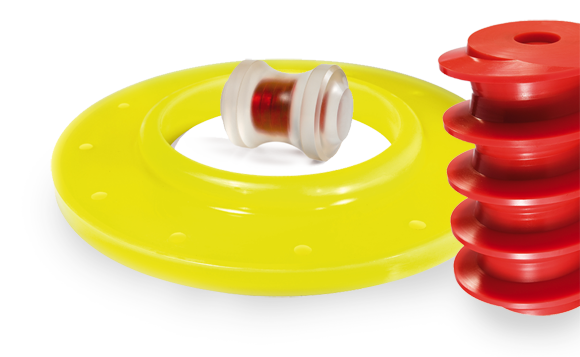

Pieffe has concentrated its core-business on cast polyurethane creating a series of production lines ranging from very low harness polyurethane (5/10 shore “A”) to higher hardness levels (85/90 shore “D”). Thanks to its extensive product range, some of which are specifically formulated for in-house laboratory applications, means that Pieffe is able to resolve even the most complex problems in a whole host of industrial sectors.

Thanks to the considerable flexibility of its production plants it is able to guarantee the production of polyurethane small parts as well as large sized and complex manufactured items. As well as small scale productions (starting from single prototypes) to those on a large scale.

The impeccable quality of Pieffe products means that they can be used in a whole host of production contexts, from the textile to the food sector, from the pharmaceutical-sanitary field to the steel and iron processing fields, from the automotive to the mining sectors, from offshore to the glass processing sector, from packaging to paper industry, not to mention wood workmanship and refuse sorting right up to the provision of ancillary components for the naval and aerospace sectors.

Pieffe production also includes the polyurethane coating of wheels, rollers, cylinders and drums of any hardness and colour with dimensions of up to 1250 mm in diameter and 5000 mm in length. Furthermore, thanks to a modern and well equipped mechanical department, Pieffe is capable of supplying its clients with such articles inclusive of cores and metallic parts.