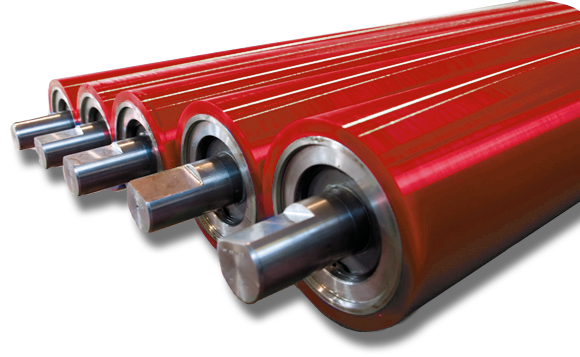

Pieffe has recently installed a new line for the coating of rollers, cylinders and drums using the widest range of elastomers currently available on the market. The plant that operates alongside the tried and tested PU coating line, has been developed making use of the latest technological advances and is capable of coating rollers of up to 1500 mm in diameter and of lengths of up to 5500 mm.

Thanks to the skill in the formulation of these compound blends, Pieffe is capable of transforming high performance elastomers to guarantee excellent quality with the aid of its in-house laboratory.

As well as the standardized operations, additional processing operations can also be undertaken such as:

- Coating of packages and head sections

- Creation of slug-breakers (single or double)

- Coatings of variable hardness (on the same table)

- Grindings with cambering (single or double)

- Conical grinding

- Bi-conical and bi-truncated conical grinding

- Axial and radial scoring

- Helicoidal scoring (single and crossed)

- Profiles on specific request